As a prominent supplier to OEM, Tier 1 and Tier 2 automotive manufacturers,

we also utilize the automotive industry’s rigorous production part approval process (PPAP) to ensure

confidence, reliability, and consistency in the Company’s production process

MACE required for vendors who supplies to Maruti Suzuki

SQ required for vendors who supplies to Hyundai & Kia

For German Automotive organization supplies

IATF Certified Company

Greenko for Conservation of Natural Resources

SMETA Award for the workplace conditions Assessment

ISO 14001 Certified Company

ISO 45001 Certified Company

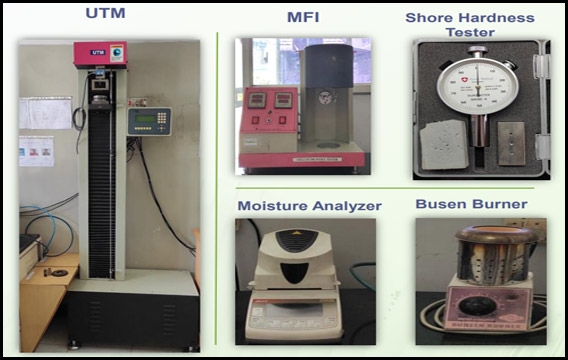

Other Quality-Focused Process and Techniques we follow “lean” production, 5-S, Six Sigma, statistical process control (SPC), and process failure mode effects analysis (PFMEA). Our project management service model also helps to provide clients with total quality assurance from start to finish.

Whether your project requires millions of units or small, pre-production quantities, your work will be handled with the same, unfailing, careful attention to detail that you warrant.

Please send us your inquiry, our team will get in touch with you

* Mandatory fields