Makino Raises the Bar in Vertical Machining Center Productivity with Next-Generation PS105

Advanced technologies and increased capacity drive new levels of productivity for job-shop production environments.

Building on its highly successful PS-Series product line, Makino introduces the next-generation PS65 and PS105 vertical machining centers.

Both models feature enhanced design characteristics and next-generation technologies that expand upon the capabilities of their predecessors. With an ideal blend of power, accuracy, speed and reliability, the PS65 and PS105 are redefining the standard for vertical machining center productivity within the aerospace, medical, automotive and general manufacturing industries.

The EDGE3 machine provides open and unrestricted access for the opera-tor to the work zone with a 4-sided programmable rise and fall work tank, and achieves reliable and repeatable precision through a stationary work table design.

The advanced technologies and intelligent design of the EDGEi-Series machines deliver an unparalleled value, capabiliry and reliable productivity to Sinker EDM operations.

The EDGE3i machine provides open and unrestricted access for the operator to the work zone with a 4-sided programmable rise and fall work tank. and achieves consistent repeatable precision through a stationary work table machine design.

The foot print of the EDGE3i is dramatically reduced by ‘me…mg the dl-eleCthc reservoir into the base casting of the machine, eliminating the need for external holding tanks. and this design enhances thermal stability coupled with the standard di-electric chiller unit. Floor space requirements are further reduCed bY integrating the ATC (Automatic Tool Change, system internal to the machine beneath the Ve structure, providing greater process efficiency and unattended operation capability.

| S.No | Standard | |

|---|---|---|

| 1 | Maximum workpiece dimensions [mm] | 1050 x 820 x 300 |

| 2 | Maximum workpiece weight[kg] | 1000 |

| 3 | XY axis table travel [mm] | 600 x 400 |

| 4 | Z axis travel [mm] | 310 |

| 5 | UV axis travel [mm] | ± 100 x ± 100 |

| 6 | Maximum taper angle°/mm>] | ± 30/150 |

| 7 | Minimum step increment of the drives [mm] | 0.0001 |

| 8 | Wire diameter [mm] | Ø 0.10 – Ø 0.30 |

| 9 | Maximum wire weight [kg] | 16 |

| 10 | Machine weight [approx.] [kg] | About 3600 |

| 11 | Controller | FANUC 31i-WB |

| 12 | Part program storage size [MB] | 8 |

| 13 | Acoustic noise level | |

| 14 | LPA [dB] | 64 |

| 15 | LPCpeak [dB] | 81 |

| Model name | Overview | Sales status |

|---|---|---|

| SG12 | High-performance Die-sinker EDM Next-generation machine incorporating the Mitsubishi Electric’s AI technology (Maisart) and control unit (D-CUBES) to pursue both high accur acy and high productivity |

On sale |

The Makino F3 is a vertical machining center (VMC) manufactured by Makino Milling Machine Co. Ltd. It is designed for high precision, high speed machining of a wide range of materials, including metals, plastics, and composites.

The F3 VMC has a compact design with a small footprint, making it ideal for small to medium-sized machining applications. It features a high-speed spindle that can rotate at up to 20,000 RPM, which enables it to cut through tough materials quickly and efficiently.

The F3 VMC is equipped with a range of advanced features, including a high-resolution touch-screen control panel that allows for easy programming and operation. It also features a rigid machine structure with a high-quality casting, linear guides, and high-precision ball screws, ensuring excellent accuracy and stability during machining.

Other notable features of the Makino F3 VMC include a high-speed automatic tool changer that can accommodate up to 30 tools, as well as a coolant system with a large capacity tank and a chip conveyor that helps to keep the work area clean.

Overall, the Makino F3 VMC is a highly versatile and reliable machine that is ideal for a wide range of machining applications, including milling, drilling, tapping, and more.

High-speed spindle: The machine is equipped with a powerful spindle motor that can reach speeds up to 8000 RPM, allowing for fast and efficient cutting of various materials.

Automatic tool changer: The BMV45 TC20 has an automatic tool changer with a capacity of up to 20 tools, which reduces setup time and improves productivity.

Control system: The machine is equipped with a Siemens 828D control system, which provides advanced programming capabilities and easy-to-use interfaces.

Work envelope: The machine has a large work envelope, with a table size of 900 x 450 mm and a maximum load capacity of 500 kg.

Rapid traverse rate: The machine has a rapid traverse rate of 30 m/min, which allows for fast movement between cuts, reducing cycle time.

Cutting performance: The machine is designed for high precision cutting of various materials, including ferrous and non-ferrous metals, plastics, and composites.

Chip management: The BMV45 TC20 has an efficient chip conveyor system that removes chips from the work area, reducing downtime and improving productivity.

These technical specifications are subject to change based on the model and configuration of the machine. It is always recommended to refer to the official documentation or consult with the manufacturer for the latest and most accurate technical specifications.

Heavy-duty turning on the long shaft

Long stroke type suitable for machining long workpieces

Overwhelming cost performance

Brilliant cutting capability realizes high productivity.

On-board conversational programming software, Turn mate I, is prepared as an option.

Minimizes the damage to the machine with retraction function by abnormal load detection.

Safety setting up by interference prevention function at debug mode.

Thanks to the thermal displacement compensation function, the long-term stable production is realized.

| S.No | Mo8JL5-II | |

|---|---|---|

| 1 | Max. machining dia. | Ø280mm/Ø65mm (Barstock) |

| 2 | Max. machining length | 500mm |

| 3 | Spindle chuck size | 8 inch |

| 4 | Main spindle speed | Max. 4,000 min-1 (Rated speed : 3,500 min-1) |

| 5 | No.Of turret stations | 8-station turret |

| 6 | Rapid traverse rate | X : 24m/min Z:27m/min |

| 7 | Main spindle motor | 9/11kw |

| 8 | WidthxDepthxHeight | 2,170mm x 1,778mm x 1,600mm |

| 9 | Weight | 3,430kg |

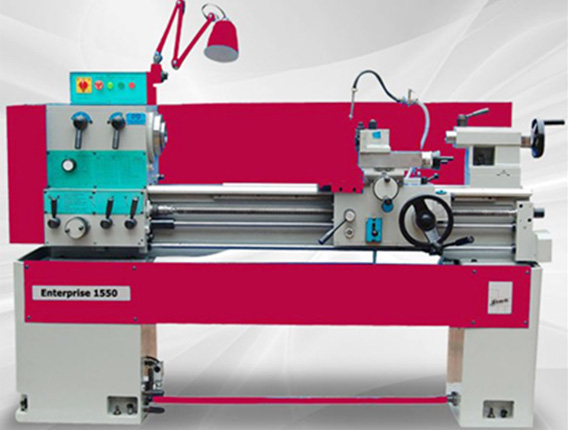

All Geared Head Lathe, comprising of hardened and ground bed, American A2-6 Spindle Nose, R.H. Hand Wheel Apron, Square Tool Post and electrical item suitable for 415V, 5HP, 50 cycles with 3.7 KW motor.

Please send us your inquiry, our team will get in touch with you

* Mandatory fields